The construction industry has long been slow to adopt new technologies, but 3D printing is changing that. Emerging as a revolutionary tool, 3D printing (also known as additive manufacturing) plays a significant role in how homes and commercial buildings are designed and constructed.

From faster project timelines to innovative materials, 3D printing is poised to reshape the entire construction process in ways that could make building homes more affordable, sustainable, and efficient.

What is 3D Printing in Construction?

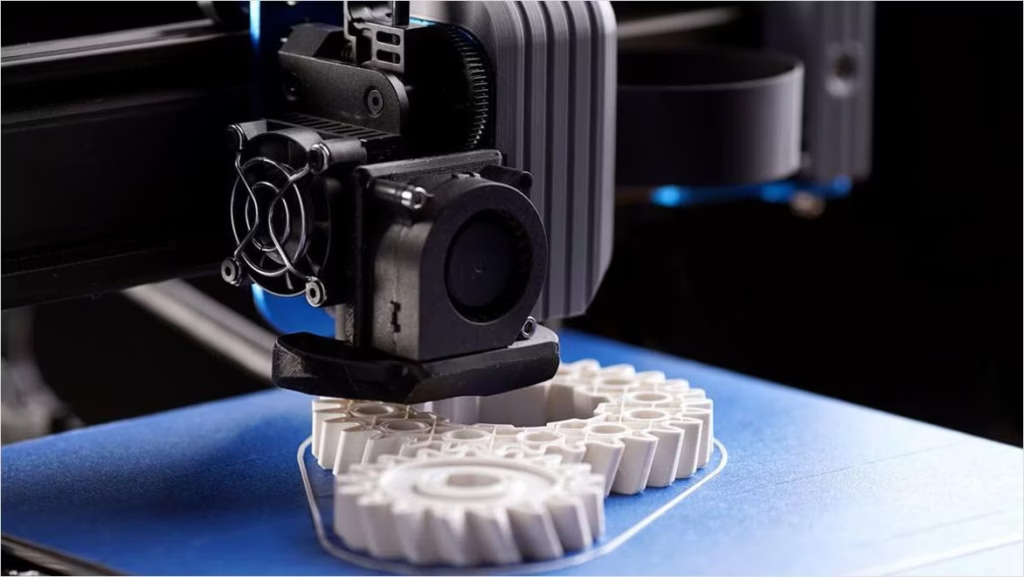

At its core, 3D printing in construction uses a large-scale 3D printer to create structures layer by layer, based on a digital blueprint. The process differs from traditional methods, which usually involve cutting, shaping, or assembling materials like wood, steel, and concrete. 3D printing extrudes materials like concrete, metal, and even recycled plastics through a nozzle, building structures with high precision. The technology can create entire buildings, including flooring and roofing components, with minimal human labor and reduced waste.

Speeding Up Construction Timelines

One of the most exciting advantages of 3D printing is its ability to speed up construction. Traditional methods can take months or years, especially with complex designs. 3D printing can drastically reduce this time, with some buildings being printed in just days. A home that might take several months to build using conventional methods could be completed in a few weeks with 3D printing. This not only accelerates the building process but also reduces labor costs associated with delays.

For instance, a home that might take several months to build using conventional methods could be completed in just a few weeks, thanks to 3D printing. This not only accelerates the building process but also reduces the labor costs associated with construction delays.

Cost Savings and Efficiency

Building a home or commercial structure with 3D printing can be more cost-effective due to reduced labor and material waste. 3D printing allows precise control over how much material is used, ensuring minimal waste. Traditional construction often involves excess materials or cuts that result in unusable pieces. With 3D printing, each layer is carefully deposited, reducing material waste. Additionally, since 3D printers create detailed structures with less labor, projects require fewer workers, lowering labor costs. This could be a game-changer for an industry often plagued by rising construction costs and labor shortages.

Additionally, because 3D printers can create highly detailed structures without the need for extensive labor, projects can be completed with fewer workers, leading to reduced labor costs. This could be a game-changer in an industry often plagued by rising construction costs and labor shortages.

Sustainable Construction

Sustainability is one of the most compelling reasons why 3D printing is gaining traction in construction. As the world faces environmental challenges, sustainable practices are a priority for both builders and consumers.

3D printing promotes sustainability in several ways:

- Use of recycled materials: Many 3D printers use recycled materials like plastic waste or industrial byproducts, reducing waste in landfills.

- Energy efficiency: 3D printing creates less material waste and can optimize energy-efficient designs, resulting in more eco-friendly structures.

- Custom designs: 3D printing can create energy-efficient designs, such as homes with better insulation or shapes that optimize airflow and sunlight.

Overcoming Labor Shortages

Labor shortages, particularly among skilled workers, have been a significant issue in construction. 3D printing helps address this problem by automating much of the building process. With 3D printers, much of the labor-intensive work is reduced, requiring fewer workers on-site. This can help construction projects progress despite the ongoing shortage of skilled labor.

Challenges and Limitations

Despite its potential, 3D printing in construction faces challenges. The technology is still new, and not all building codes and regulations are designed to accommodate 3D-printed structures. In some regions, 3D-printed buildings remain experimental, and government regulations have yet to catch up to the technology.

Another limitation is the size of the printing machines. While large-scale 3D printers can create significant structures, there is still a limit to how large a building can be printed. For particularly large structures or skyscrapers, traditional methods are still required. Finally, the materials used in 3D printing are still evolving. While concrete and other materials can print walls and foundations, the technology is not yet widely used for complex elements like plumbing, wiring, or roofing systems. These components still need traditional construction methods.

The Future of 3D Printing in Construction

As the technology advances, we can expect to see 3D printing become an increasingly integral part of the construction industry. Researchers and companies are continually working to develop new materials that are stronger, more versatile, and better suited for 3D printing.

Moreover, as building codes and regulations adapt to these new technologies, 3D printing will likely play a larger role in both residential and commercial construction. Its potential for reducing costs, improving efficiency, and providing sustainable solutions makes it a technology worth watching in the coming years.

3D printing is revolutionizing the construction industry by enabling faster, more cost-effective, and sustainable building practices. From creating affordable housing solutions to minimizing material waste and reducing labor costs, 3D printing is changing the way we think about construction. While the technology is still evolving and faces some challenges, its impact on the industry is undeniable, and the future of building could very well be printed—layer by layer.

With the right financing partner like Pacific Equity and Loan, developers and investors can ensure that their cutting-edge projects get the funding they need to thrive in the rapidly changing world of 3D printing construction. If you’re looking to bring innovation to life in your next real estate project, consider Pacific Equity and Loan to help you take the next step.

Sources:

Sources: redfin. Forbes. attom.